For large motors on drives (over 100 HP/75kW), we recommend an AEGIS® Shaft Grounding Ring at one end of the motor, and an insulated or hybrid/ceramic bearing at the opposite end. People often ask us, "Why not use two AEGIS rings, one at each end?"

Two Different Bearing Currents

When motors on drives are well-grounded/bonded back to the drive, the two bearing currents you need to worry about are 1) shaft voltage discharge/EDM current, which occurs in all motors on drives, and 2) high-frequency (HF) circulating current, which is mainly a problem in motors over 100 HP/75 kW.

Shaft voltage discharge usually comprises a single arc through the bearing. It's fast - under 0.1 microseconds (one ten-millionth) - but fairly small, ranging from 0.5 to 3 amps peak. HF circulating current goes on for longer - instead of one pulse, you get current cycling back and forth (a decaying sine wave, for the electrical engineers) - and is larger, with peak values up to 20 amps.

Lessons from History

In the early days of AEGIS rings (~2007), we recommended two rings, one at each end of the motor, to divert circulating current around the bearings. At first glance, this is a good idea - if an AEGIS ring can bleed off shaft voltage by carrying current around the bearing, then one at each end should protect both bearings. In reality, this is not always a good idea.

In some installations with very high circulating current, the combination of high amplitude and long duration can be enough to electrically wear AEGIS rings. In these problem cases, the grounding rings work for a few months or years, and then stop functioning. Electrical bearing damage then quickly sets in.

It was a painful lesson, but we learned it quickly. It is difficult to predict whether a motor will have HF circulating current large enough to preclude the two-AEGIS method, so to play it safe, we stopped recommending it at all.

Best Practices for Motors over 100 HP/75 kW

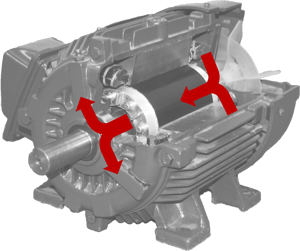

For motors on drives large enough for circulating current to be a risk, we now recommend the following:

- One AEGIS ring (usually at the drive end) to dissipate shaft voltage and prevent EDM. For low voltage motors up to 300-500 HP/225-375 kW, an AEGIS SGR is adequate. Larger and medium voltage motors require an AEGIS PRO Ring.

- One insulated or hybrid bearing at the opposite end from the AEGIS ring to interrupt circulating current

This approach has been verified by thousands of successful installations over the past 20 years. An insulated bearing is usually enough protection, but in some cases a hybrid bearing may be necessary to prevent circulating current from flowing.

In cases where an insulated or hybrid bearing is impractical, common mode chokes may be used. They may or may not eliminate HF circulating current, but they will at least reduce the risk of bearing failure. Common mode chokes, sometimes branded "inductive absorbers," cannot prevent shaft voltage buildup and discharge, so they should be used in combination with an AEGIS ring for full protection.

Summary

- Shaft voltage discharge creates a risk of premature bearing failure in all motors on drives

- High frequency circulating currents are an additional risk in large motors on drives (over 100 HP/75 kW)

- AEGIS Shaft Grounding Rings protect against bearing damage from shaft voltage discharge

- Shaft voltage discharge comprises very rapid arcs, whereas circulating current arcs back and forth through the bearing in a continuous wave

- Protecting against circulating current with two AEGIS rings, one at each end of the motor, is not recommended

- The best practice is to install an AEGIS ring at one end of large motors, and use an insulated or hybrid bearing at the opposite end

AEGIS Rings come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.