There are a number of factors to consider when deciding whether to repair or replace a damaged motor. These include (but are not limited to) the age and general condition of the motor, the availability of a suitable replacement (including the size and horsepower), and the energy efficiency of the motor versus a newer motor.

But if you decide that a motor is worth repairing, protecting it from electrical bearing damage makes good sense from both an operational and a financial standpoint. Installing an AEGIS® Shaft Grounding Ring — or having your motor repair shop install one — is one of the least expensive "insurance policies" you can buy, especially if the motor is controlled by a variable frequency drive (VFD).

By controlling the speed of motors, VFDs can improve process control and reduce  energy usage/costs by 30% or more. But VFDs induce voltages on the shafts of the motors they control — voltages that can damage bearings. And even motors not controlled by VFDs can sustain bearing damage due to stray currents.

energy usage/costs by 30% or more. But VFDs induce voltages on the shafts of the motors they control — voltages that can damage bearings. And even motors not controlled by VFDs can sustain bearing damage due to stray currents.

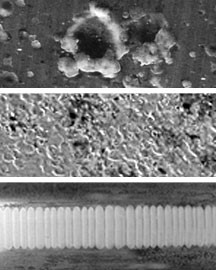

Without bearing protection, shaft voltages can discharge through bearings, causing pitting (tiny fusion craters in metal bearing surfaces), frosting (widespread pitting), or fluting (washboard like ridges in the bearing race due to the operational frequency of the drive) and complete bearing failure — sometimes in as little as 3 months!

To protect VFD-driven motors from electrical bearing damage, long-term bearing protection is needed. As proven in millions of installations worldwide, AEGIS Shaft Grounding Rings channel harmful voltage discharges away from bearings and safely to ground, protecting motor bearings for their full L10 life.

AEGIS SGR Rings are available for low-voltage, low power motors, while AEGIS PRO Series Rings are designed for medium-voltage motors, generators, and turbines, as well as large low-voltage AC motors (500 HP or greater) and DC motors (300 HP or greater).

AEGIS Rings are available in solid rings (for installation before motors are put into service) and split rings (for fast, easy installation on coupled or in-service motors). AEGIS uKITs include an AEGIS Ring (solid or split) and a set of mounting brackets that speed and simplify installation on motors with shaft shoulders, slingers, or other end bell protrusions.

Most motor repair shops can install AEGIS Rings in-house or in the field, using best practices to protect new, in-service, or refurbished motors.

For motors up to 100 HP, an AEGIS Ring is typically all you need to protect motor bearings and coupled equipment from electrical bearing damage.

Motors greater than 100 HP and medium-voltage motors, however, are subject to high- frequency circulating currents as well as capacitive shaft voltage discharge bearing current. So to adequately protect these motors, install an AEGIS Ring on the drive end of the motor and an insulated bearing on the non-drive end. For low-voltage motors less than 500 HP, use an AEGIS SGR. For low-voltage motors greater than 500 HP or medium-voltage motors, use an AEGIS PRO Series Ring.

frequency circulating currents as well as capacitive shaft voltage discharge bearing current. So to adequately protect these motors, install an AEGIS Ring on the drive end of the motor and an insulated bearing on the non-drive end. For low-voltage motors less than 500 HP, use an AEGIS SGR. For low-voltage motors greater than 500 HP or medium-voltage motors, use an AEGIS PRO Series Ring.

Regardless of the type of AEGIS Ring you install, be sure to thoroughly clean the motor shaft and apply AEGIS Colloidal Silver to the shaft in the area where the ring's microfiber brushes will contact it. Or ask your local motor shop to install AEGIS Rings on any motors they repair for you!

To download an AEGIS Bearing Protection Handbook which details best practices for diagnosing failed motors, testing in-service motors for damaging shaft currents, and protecting at-risk motors from electrical bearing damage, click here.

And if you decide that a motor is not worth fixing, choose a new replacement motor with an AEGIS Ring factory installed either internally or externally. For a list of manufacturers that offer motors with AEGIS Shaft Grounding Rings factory-installed, click here.