A couple of months ago, we published a Q&A post including an account of electrically damaged insulated bearings. We got a few questions about that one. “Aren’t insulated bearings supposed to block bearing current? Then how did they get damaged?” Let us explain. (Make yourself comfortable.)

All electric motors on drives are subject to shaft voltage buildup. So they’re all at risk of damage from shaft voltage discharging through the bearings. That’s what AEGIS® Shaft Grounding Rings are for: they bleed off shaft voltage before it gets high enough to discharge. Larger motors on drives, over 100 hp/75 kW, are also subject to high frequency (HF) circulating currents. An AEGIS ring alone can’t stop circulating currents, because they go through both bearings simultaneously, in opposite directions. And though it seems like an AEGIS ring at both ends of the motor should work, we’ve found that it can backfire.

So for larger motors we recommend using some type of insulated bearing at the opposite end from the AEGIS ring. A ceramic bearing is perfect, but insulating sleeves and insulation-coated bearings are also fine. At least, they are most of the time.

These bearings are made of steel, with a thin layer of aluminum oxide on one race (typically the outer race). So you end up with a thin non-conductive layer between the bearing and the motor frame. Ordinarily, that insulating layer is enough to break the circuit so circulating current can’t flow. In order to flow at all, it must flow at both ends: Onto the rotor at one end, and off it at the other. Insulated bearings block that flow at one end, and that’s all it takes.

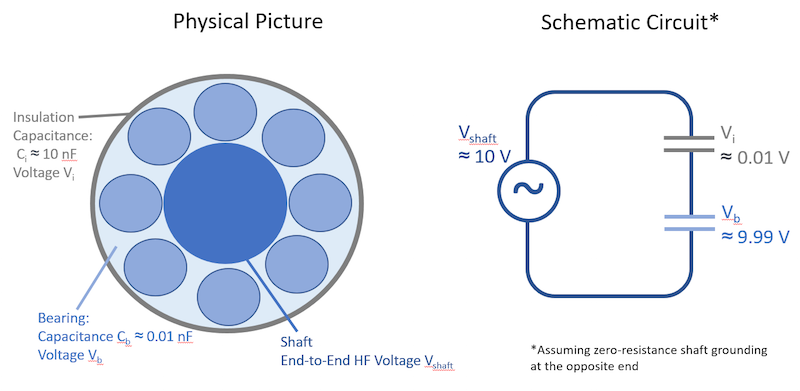

But whenever you have a thin layer of insulator between two conductors, you have a capacitor. Together, the bearing’s outer race, alumina, and bearing housing make a capacitor. The bearing itself also has some smaller capacitance. Now, HF circulating current is driven by a HF end-to-end voltage on the shaft. To that voltage, the bearing, insulation, and housing look like two capacitors in series. Because the bearing’s capacitance is lower than the alumina’s, most of that voltage ends up across the bearing.

Model circuit of an insulated bearing. With the ballpark figures given for capacitances and shaft voltage, 99.9% of the voltage ends up across the bearing.

In the rare cases where insulated bearings fail, that voltage is enough to cause arcing through the bearing. At the other end, current would flow in the other direction through the grounding ring (if installed) or the other bearing, to complete the circuit. Again, this problem is rare. 99% of the time, an ordinary insulated bearing will not be damaged by circulating currents. At least, not fast enough to cause premature failure.

In the rare exception, you’ve got options. A hybrid bearing will solve the problem. No current can make it through a ceramic rolling element. Admittedly, hybrid bearings are expensive. But if you’ve already had an alumina-coated bearing fail, you have to ask: What’s more expensive? A ceramic bearing, or the downtime from another unexpected failure?

You can also try an insulated inner race. Because it’s smaller, an insulated inner race will have less capacitance than an insulated outer race. Having less capacitance in the insulation makes for less voltage across the bearing. So breakdown (arcing) is less likely.

Another thing you can try is common mode chokes, sometimes branded as “inductive absorbers.” Chokes decrease HF circulating current. We don’t have any hard data on this, but the combination of choke and insulated bearing may prevent HF circulating current damage. At the very least, adding chokes will slow down damage to an insulated bearing.

In any case, you would still want an AEGIS ring at the opposite end from the insulation. Neither chokes nor a single insulated bearing will protect the other bearing against shaft voltage discharge.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.