Q1. Should we put a shaft grounding ring on the driven equipment as well, or is a motor grounding ring sufficient?

A1. A shaft grounding ring on the motor is usually enough. Say the motor is driving a gearbox. If you put a shaft grounding ring on the motor, it should bleed off the vast majority of voltage on the shaft. You do need to make sure the shaft grounding is sufficient: If the motors are larger than a few hundred hp (kW), or run on more than 600V, you need a PRO ring rather than an SGR. It's also always a good idea to bond the motor frame and the load frame with a high-frequency grounding strap.

Q2. What if you use ceramic or hybrid bearings at both ends?

A2. That will protect the motor bearings from electrical damage just fine. But there will still be a capacitive voltage on the shaft, and that voltage will discharge if it can. So whatever machine the motor is driving will be at risk.

We had a paper mill customer that was losing bearings regularly. Someone from a bearing distributor told them they should install hybrid bearings. They did, and after that, the motors were fine... but the gearboxes those motors were driving started taking damage. Eventually, they installed AEGIS rings on the motors, and the gearboxes have been fine since.

So even if both motor bearings are insulated, you should still use shaft grounding to protect the driven equipment's bearings.

Q3. Why do we mount shaft grounding rings on only one end of the motor?

A3. You might think that if one ring is good, two rings are better, one at each end. It turns out that's overkill, at best.

Small motors under 100 hp (75 kW), only need one SGR. A second wouldn't hurt them, but it won't help. Once you make the electrical connection with a grounding ring at one end, the entire shaft is basically neutralized. Adding another point of electrical contact doesn't make much difference.

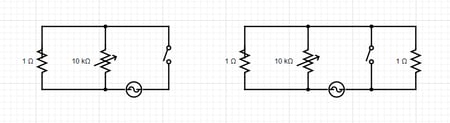

For larger motors, over 100 hp, it can actually worsen bearing damage from high frequency circulating current. How does that work? We recommend a shaft grounding ring at one end, and interrupting circulating current with an insulated or hybrid bearing at the opposite end. That's like opening a switch in a circuit, as shown in the figure. The bottom is the motor shaft; the top is the frame. The ac source is an inductive voltage on the shaft, the grounding

ring is the 1Ω resistor, the steel bearing is the 10 kΩ variable resistor, and the ceramic bearing is the open switch.

The conductive path is broken, so no current flows. Putting a shaft grounding ring at the end with the insulated bearing is like dropping a paperclip across an open switch: The circuit is complete again, and current can circulate. And some of that circulating current will find its way through the uninsulated bearing and damage it.

Long story short: You only need one grounding ring for any motor, and for larger motors, you also need an insulated bearing opposite the grounding ring.

AEGIS Shaft Grounding Rings have a 2-year extended warranty against bearing fluting damage. No other form of shaft grounding offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and – pandemic restrictions permitting – we can also visit your facility to review your exact application.