Part 15 in a series of questions and answers from our Q&A webinars.

Q1: I know AEGIS® Rings protect motor bearings from electrical damage. But what about the load? Does the equipment being driven need protection, too?

A1: If you have a motor on a drive, and induced shaft voltage, that voltage can discharge either through the motor's bearings or the loads. Be it a pump, gearbox, or whatever. The vast majority of the time, this will take care of it:

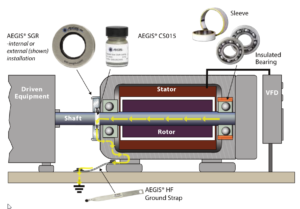

- Install one shaft grounding ring on the motor. This will protect the motor and load bearings from shaft voltage discharge.

- Bond the motor frame to the load frame with a high-frequency grounding strap. This will protect the motor and load bearings from possible rotor ground current.

- If the motor is over 100 hp/75 kW, you should also insulate the motor bearing opposite the AEGIS ring. This will block potential high-frequency circulating current.

To some extent, you can replace #2 and #3 with an inductive core, but we have not exhaustively tested this. We have thoroughly tested the practices above, and we know they work. We do occasionally see people put one grounding ring on the motor and another on the load, but this isn't usually necessary if you use a grounding strap between the motor and load.

Q2. Would it be better to spec a motor with a grounding ring if a VFD is specified to control the motor?

A2. Yes, but there are some complications here. Sometimes you don't know if you'll be using a drive; sometimes it's determined after the fact; sometimes it's decided at the last minute that drives will be used, but no provision is made for shaft grounding.

There's also a fairly good chance that a motor's not specified to go on a drive, but it will - a year or five down the road - end up on a drive.

In all of those cases, if you get a motor with AEGIS, then it will be protected in the event that it does end up on a drive, either from the start of a few years down the line.

Q3. Should AEGIS be installed in all motors, regardless of whether they're supplied by a VFD?

A3. If the motor's not on a VFD, you'd need some other condition to  require an AEGIS ring. If your application involves a lot of static electricity, then it would make sense to install AEGIS. If you're rolling mylar film or vinyl flooring, for instance, the material will pick up static and that can discharge through the bearings of the rollers or the motors driving the conveyors.

require an AEGIS ring. If your application involves a lot of static electricity, then it would make sense to install AEGIS. If you're rolling mylar film or vinyl flooring, for instance, the material will pick up static and that can discharge through the bearings of the rollers or the motors driving the conveyors.

It certainly simplifies things to be prepared so you don't have unexpected failures. But if you just have a motor, not on a drive, with no static problem, an AEGIS ring won't help, unless you add a drive in the future, as discussed above.

AEGIS Rings come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

![]() To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.