WEG Electrics's new W22 Magnet Super Premium motors meet the IE4 efficiency levels according to IEC standard 60034-30-1. The magnets inserted into the rotor ensure a significant reduction in electric losses, and thus the motor temperature, enabling smaller frame sizes to be utilized. Compared to induction motors of the same output and speed, the weight and volume of the equivalent W22 Magnet Super Premium motors is reduced by as much as 77% (refer to example below). The W22 Magnet motors operate with lower temperature rise even at low speeds.

Applications

Cooling towers, bag filters, paper machines, paper coil winders, conveyors, pumps, looms, direct current (DC) motor replacements, extruders, compressors, fans, etc.

WEG Electric W22 Magnet Drive Motor with AEGIS installed FRAMES 364T and above

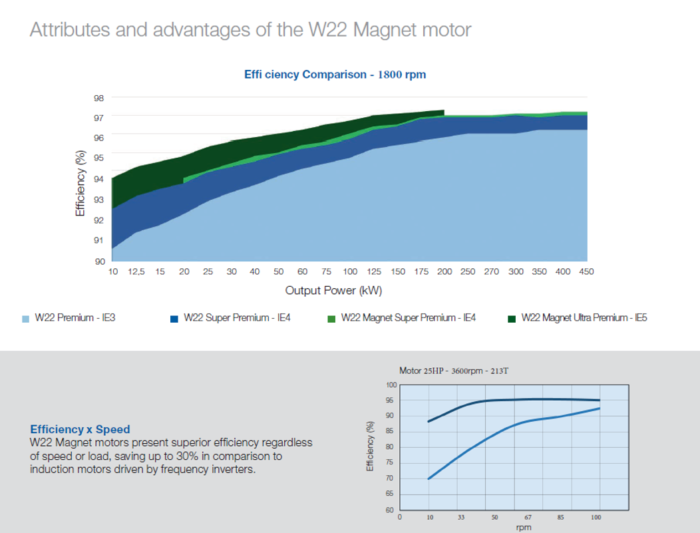

WEG Electric W22 Magnet Drive Motor with AEGIS installed FRAMES 364T and aboveThe W22 Magnet Drive System composes premium and ultra premium efficiency motors with permanent magnets driven by frequency inverters. Perfect for applications where speed variation, precise control at low speeds, low noise levels and compact design are critical. This technology provides the motor with significant advantages such as higher efficiency and a greater power density per frame. They are driven by WEG CFW11 frequency inverters, which offer constant torque across a wide speed range, operating even at low speeds with efficiency levels above induction motors without requiring forced ventilation. W22 Magnet motors are available in Super Premium (IE4) and Ultra Premium (IE5) versions – the highest efficiency available on the market today. Due to the dedicated software application which incorporates the vector control technology for driving permanent magnet motors, the use of the WEG CFW-11 frequency inverter and W22 Magnet motor is mandatory.

Efficiency Comparison Chart: Black line is W22 Magnet; Blue line is Induction Motor

Efficiency Comparison Chart: Black line is W22 Magnet; Blue line is Induction Motor