Eaton Electrical published an article today; entitled Downtime can be disastrous. While the article focused on data centers and their need for uninterruptible power supplies (UPSs), the general lesson applies to every business: Downtime, especially unplanned downtime, is so expensive that predictive maintenance programs are a must.

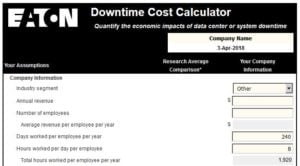

But the most interesting thing about the article was a link to a web app that Eaton developed: The Downtime Cost Calculator. You fill out an interactive form with business-related quantities like annual revenue, number of employees, and so on. Then the application automatically calculates your cost  of downtime, broken down into cost per event, cost per hour, and even cost per minute!

of downtime, broken down into cost per event, cost per hour, and even cost per minute!

This may be a handy tool for today's busy maintenance manager. At the very least, it will help to make the case that preventive maintenance is a good investment!

Upper managers need to understand that decreasing unplanned downtime - and when possible, preventing downtime in the first place - is key to efficient operations and sustaining profitability in every industry.

One example of downtime prevention is installing bearing protection on motors driven by variable frequency drives (VFDs). VFDs can destroy motor bearings in as little as a few months, potentially shutting down production or HVAC systems. This failure is preventable with AEGIS® shaft grounding rings. AEGIS rings can easily be installed in the field or during motor repair. But the easiest and least expensive solution is to buy motors with AEGIS factory-installed.