Part 2 in a series of questions and answers from our Q&A webinars.

Q: Where can I purchase AEGIS rings, and how long does it take to get them?

A: We have distributors around the world. You can find your regional distributors here. As for lead time: We make most of our parts to order, and stock parts can almost always ship from Maine (USA) within one business day. We also have a few stocking distributors, like Bartlett Bearing and Midpoint Bearing. They keep a large inventory, and might be able to get you an SGR even faster.

Q: Is it better to put a grounding ring at the drive end (DE) or the non-drive end (NDE) of the shaft?

A: In most cases, it doesn't matter. It's usually easier to mount at the DE if you're mounting the ring externally. The one time it matters is in motors over 100 hp, where the NDE bearing is insulated. In that case, you need the ring at the other end. In the unusual case that the DE bearing was insulated, but the NDE was not, you would have to put the ring at the NDE to keep it opposite from the insulation.

In vertical motors, you want to insulate the top bearing, and mount the AEGIS ring at the lower bearing.

Q: If you have insulated bearings, do you still need AEGIS?

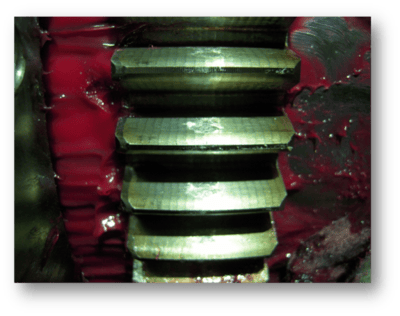

A gear in a gearbox damaged by shaft voltage discharge

A gear in a gearbox damaged by shaft voltage dischargeA: We recommend it. In high-capacity/high-value and critical applications, you often have two insulated bearings on motors. But with insulated bearings, shaft voltage is still there. It can discharge through coupled equipment.

Example: One company had a 600 hp motor in a paper plant. They had a lot of bearing failure, so they put in two insulated bearings. Then the motor was fine. BUT the shaft voltage was still there, and ended up discharging through & damaging the gearbox! So they protected their $50k motor but had to repair their $250k gearbox. That was even more expensive to repair than the motor was.

Q: What is the safe horsepower range of AEGIS rings, and at what point do you need an insulated bearing?

A: There are two kinds of AEGIS grounding ring: SGRs and PRO Series rings. For ac motors under 600 V and up to 500 hp (375 kW), an SGR is fine. We'll talk about dc motors separately.

With ac motors over 100 hp (75 kW), you also need an insulated bearing, usually at the non-drive end. That's because larger motors can get high-frequency circulating currents as well as shaft voltage problems. An AEGIS ring can bleed off the shaft voltage, no problem. And it can protect the bearing it's mounted at from circulating current, but it can't protect the other bearing. You need an insulated bearing for that. (Common mode chokes are also believed to help with circulating currents.)

For ac motors over 600 V or over 500 hp, you need PRO rings (and an insulated bearing). These larger motors can get more charge flowing off the shaft, so PRO rings have more conductive fibers to carry more current. Keep in mind that PRO rings are custom parts, so the lead time is longer than for SGRs.

As for dc motors, things are a little different. Small dc motors, 10 hp (7.5 kW) or less, only need an SGR. But any bigger than that, and they need an insulated bearing. And we recommend PRO rings for dc motors over 300 HP (225 kW).

Q: In large motors, why can't you just use a second AEGIS ring at the opposite end, instead of an insulated bearing?

A: You would think that would work, right? It makes sense that if you had an AEGIS ring at both ends, then circulating currents would just run from frame to shaft through the rings, and leave the bearings alone. We used to think that too. And sometimes it does work.

But sometimes it doesn't. The problem is that sometimes circulating current will go through the rings and through the bearings. The rings always carry most of the current, but sometimes you still get enough leaking through the bearings to damage them.

That's why we recommed an insulated bearing for circulating currents, because insulation will stop these currents dead. And we don't recommend anything that will only probably work. All of our recommendations and best practices, are based on years of experience of what works 99+% of the time.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.