Q1. Are there any municipal/metro railways that use shaft grounding rings on their electric trains?A1. Yes, but we aren't really at liberty to name names. We can tell you that AEGIS Rings are on trains in several municipal rail systems in the US, and also in several countries in Europe and Asia.

One thing about rail applications: There's a lot more variability in design than in industrial motors. In rail, you've got to be careful to position the grounding ring at the right place, and how you mount it, and so on. We've got a lot of experience with this, and we want to help you get it right on the first try, so if you have a railway application, give us a call and we'll work through it with you.

Q2. Can shaft grounding rings be used in submersible well pump motors?

A2. Grounding rings can't be submerged in water or oil. Oil is insulating, and when the shaft and fibers are coated with it, it prevents charge from moving from shaft to fiber. Water is more conductive than oil, but it still interferes with conduction from shaft to fiber.

But just like with rail, there's a lot of variability. We do have some situations where submersible or jet pumps have a cavity in the motor or the pump where a grounding ring will fit, but that's a special case.

Oftentimes, if the motor is big enough, can find a place to put a grounding ring, but it's all case by case.

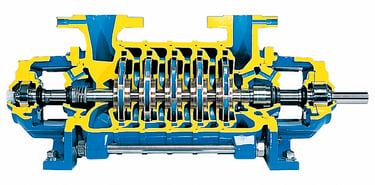

Q3. I've seen extreme corrosion on a multiple-stage pump where the case failed. We had bearing failure coupled with extreme case corrosion. We couldn't figure it out.

A3. In waste/freshwater pumping, you've got lots of pumps moving liquid, and you can have electrolysis of the pump, pipe, or other metal objects. It can do strange things. We had an MRI machine manufacturer that was pumping pure water for cooling, driven by a motor on a drive. After six months they got leaks in all of their piping. This only started after they'd switched from a standard motor to one with two insulated bearings.

It was electrolysis: Their formerly pure water was now full of copper and zinc and other electrolytes. With their old motor, the shaft voltage had discharged through the bearings. When they switched to a motor with two insulated bearings, the shaft voltage couldn't go through the bearings anymore. So it made its way to the pipes and ended up discharging through the water, corroding the pipes and joints in the process.

AEGIS Shaft Grounding Rings come with a 2-year extended warranty against bearing fluting damage. No other form shaft grounding offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and – pandemic restrictions permitting – we can also visit your facility to review your exact application.