VFD-induced shaft voltage damages motor bearings and shortens motor life

If you’re using variable frequency drives (VFDs) or inverters to control motors, the motors are at risk of electrical bearing damage that can dramatically shorten their lives.

VFDs induce harmful voltage on motor shafts — voltage as high as 40 volts peak — that can destroy bearings in as little as 3 months!

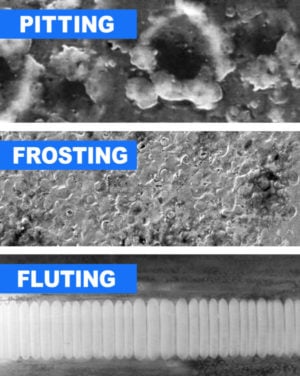

This shaft voltage builds up until it discharges by arcing through the bearings, thousands of times per second. Discharge through the bearings burns and contaminates the lubricant, drastically reducing its effectiveness. Each discharge also blasts a tiny pit into the bearing surface. Over time, this pitting results in fluting, bearing failure, and costly unplanned downtime. While most motor manufacturers offer “inverter-duty” or “inverter-ready” models, these motors usually have only inverter-rated insulation to protect their windings, but nothing to protect their most vulnerable components — their bearings.

AEGIS® Shaft Grounding Rings avert electrical bearing damage by providing a low-resistance path from the shaft to the motor frame. They dissipate shaft voltage before it can build up to levels high enough to arc through the bearings. By mitigating electrical bearing damage, AEGIS Rings protect motor users from the expense and hassle of unplanned downtime.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.