In the meantime, we had an awesome web seminar hosted by Plant Services (Now Available On Demand) with content discussing how to protect bearings from electrical fluting damage. You can view the seminar at your convenience by simply following the link.

3 Key takeaways you will get from this webinar:

- Controlling motors with variable frequency drives (VFDs) — also known as variable speed drives (VSDs) or inverters — provides increased control of motor speed or torque and can save 30% or more in energy costs.

- But VFDs can damage motor bearings, and the costs of replacing bearings/motors and process downtime can quickly eat up any savings from their use.

- Plant personnel can protect motors from VFD-induced bearing damage by providing an alternate path to ground for damaging shaft currents.

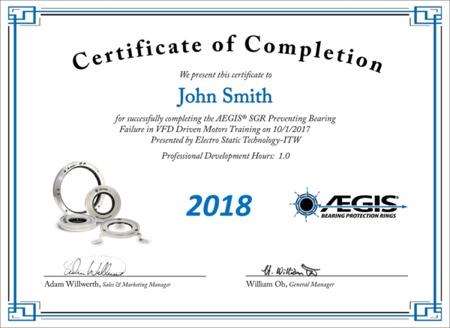

The AEGIS WebEx seminars offer you the following Certificate of Completion worth one professional development hour:

The seminar takes about one hour, with time for questions included, and is delivered by experts in the field of shaft grounding and bearing protection. Topics covered are:

- Influential research and IEEE papers on electrical bearing damage

- What bearing failures cost and ROI when mitigation is implemented

- Identifying and describing the sources and effects of bearing currents

- Testing which can be done to identify the issue

- Description of the damage to the bearings and how to identify it

- Best practice recommendation for various motors

- High-frequency bonding

- Shaft grounding technology - shaft grounding rings

- Application guidelines

- AEGIS 2-Year Warranty against bearing fluting damage

- AEGIS Bearing Protection Handbook