The American Iron and Steel Institute estimates that 20% of the cost of producing a ton of steel comes from consuming energy, whether from electricity, natural gas, coal, or from other sources. So increasing energy efficiency per ton of steel produced is one of the critical factors in sustaining profitable production.

Reducing the energy consumption of steel manufacture has benefits beyond simple profitability: It also reduces the industry's environmental footprint. One of the key technologies used to save energy is variable frequency drives (VFDs), used to control the electric motors in steel production. VFDs can allow savings of up to 30% or more in energy costs, and when integrated into modern steel production equipment, they also allow production processes and efficiencies to be improved through precise control of motors' speed and/or torque.

Modernizing existing facilities or adding new production lines as capacity and demand increase often includes the integration of VFD into the equipment design. The result of these modernizations is production improvements, which have contributed to dramatically lowering the number of man-hours used to produce a ton of steel from more than 10hrs/ton in the 1980's to 2hrs/ton or even less than 1hr/ton for finished steel [source: Profile of the American Iron and Steel Institute 2017]

Modernizing existing facilities or adding new production lines as capacity and demand increase often includes the integration of VFD into the equipment design. The result of these modernizations is production improvements, which have contributed to dramatically lowering the number of man-hours used to produce a ton of steel from more than 10hrs/ton in the 1980's to 2hrs/ton or even less than 1hr/ton for finished steel [source: Profile of the American Iron and Steel Institute 2017]

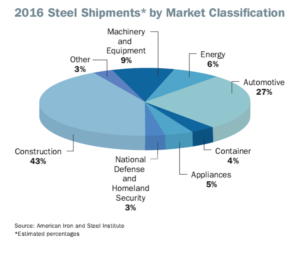

"High-strength and versatile, steel is the material of choice for many key markets and customer sectors. The automotive, construction, container, transportation and infrastructure, energy and national security sectors all depend on steel to be competitive in the global marketplace." THOMAS J. GIBSON, President and CEO, American Iron and Steel Institute

VFDs Can Lead to Bearing Failure

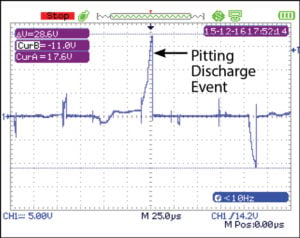

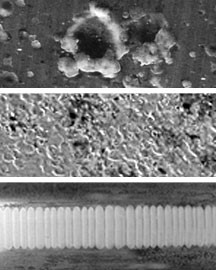

But productivity can only be increased if the motors stay up and running. If a motor's bearings fail and the line must be shut down, the costs can be staggering. Even a short interruption may cost tens of thousands or even millions of dollars in downtime, lost production, and motor repair or replacement. When a motor is run operated by a VFD, its bearings are vulnerable to electrical discharge damage. This is because the VFD produces a common mode voltage in the stator windings of the motor which is then capacitively coupled to the motor's shaft. Voltages of only 20 to 40 volts peak [source: NEMA MG1 Part 31.4.3.3] can cause millions of electrical discharges in the motor's bearings and result in fluting damage and failure.

But productivity can only be increased if the motors stay up and running. If a motor's bearings fail and the line must be shut down, the costs can be staggering. Even a short interruption may cost tens of thousands or even millions of dollars in downtime, lost production, and motor repair or replacement. When a motor is run operated by a VFD, its bearings are vulnerable to electrical discharge damage. This is because the VFD produces a common mode voltage in the stator windings of the motor which is then capacitively coupled to the motor's shaft. Voltages of only 20 to 40 volts peak [source: NEMA MG1 Part 31.4.3.3] can cause millions of electrical discharges in the motor's bearings and result in fluting damage and failure.

Protecting Bearings from Harmful Shaft Voltages

The problem of shaft voltage and bearing currents can be solved by following a proven set of best practices outlined in the AEGIS® Bearing Protection Handbook. Motors of any size may be protected from premature bearing failure with the application of AEGIS Shaft Grounding Rings, along with insulation of the opposite bearing for motors over 100 hp.

Case in Point

Several years ago a prominent steel manufacturer in the US installed AEGIS rings on their galvanizing line. From there the galvanized steel was transferred over to the rolling mill where it was rolled to the correct thickness for consumer goods like washing machines. On this line they installed six AEGIS PRO Series rings on the rolling mills. These rings had O-rings installed to retard the flow of grease into the ring. They were all mounted on the outside of the mills.

Several years ago a prominent steel manufacturer in the US installed AEGIS rings on their galvanizing line. From there the galvanized steel was transferred over to the rolling mill where it was rolled to the correct thickness for consumer goods like washing machines. On this line they installed six AEGIS PRO Series rings on the rolling mills. These rings had O-rings installed to retard the flow of grease into the ring. They were all mounted on the outside of the mills.The AEGIS PRO Series design provides reliable shaft grounding for large AC induction motors, medium voltage applications, and generators and turbines. By diverting harmful shaft voltages to ground, they protect the bearings from electrical damage and extend bearing life.

Designed for:

- Large frame low-voltage motors: 500 HP (375kW) or greater

- Medium-voltage motors

- DC motors: 300 HP or greater

- Available in shaft diameters from 2.5” to 30” [63.5mm to 762mm]

- Aluminum or stainless steel construction

- Solid and split ring designs

- Monitoring ring option for voltage monitoring