Motor repair is a competitive business. Many owners are selling to larger companies in an industry-wide wave of consolidations. Those who remain independent need every competitive advantage they can get.

Expertise Earns Loyalty

One critical advantage is customer loyalty. It is no longer possible to get by with only one-time customers if it ever was. To earn and keep your customers' loyalty, you need many things. One of these is to show them your expertise. They need to see that you understand their problems and can deliver solutions.

Expertise commands a premium. If you needed your car repaired, would you take it to Duct Tape Al's Discount Garage? If you wanted the problem to stay fixed, you would go somewhere you trust more than the duct tape guy. If higher-end companies charge a bit more for their services, that's because their services are more valuable.

The single most valuable service you can offer is protection against unplanned downtime, the bane of every production and facility manager. For this reason, many motor repair companies have branched into predictive maintenance and related services. Other value-adding services can be offered right from your machine shop.

For Example...

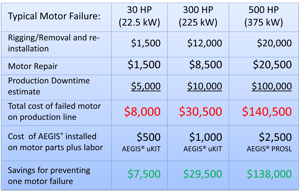

Offering shaft grounding service is one example. Considering the cost of unplanned downtime, shaft grounding offers a great return on investment for your customers. Approximate costs and benefits are shown in the table to the right.

Most, if not all, motor repair companies are aware of the risk of electrical bearing damage for motors controlled by VFDs (ANSI/NEMA AR100, Section 2.2). However, it's unclear how many motor users are aware of the risk of premature motor bearing failure. Detecting electrical damage by cutting and inspecting failed bearings for fluting, risk mitigation by installing AEGIS(R) Shaft Grounding Rings, and monitoring for risk by on-site shaft voltage testing are all good ways to show your expertise and add value to your repair service.

In Summary

Like most companies, motor repair businesses depend on repeat customers. One way to build and retain loyalty is to show your customers that you understand their problems and how to mitigate them. Your industrial customers' most expensive problem is unplanned downtime. Any downtime-reducing service you can offer that your competitors can't is a huge advantage.

As far as other forms of electrical bearing protection go, AEGIS rings come with a 2-year extended warranty against bearing fluting damage. No other form of shaft grounding comes with a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.