Today, there are hundreds of types and blends of plastics, and they can be formed, molded, extruded, blown, and otherwise fashioned into a dizzying array of products. Processing equipment must be precisely controlled to ensure the quality, durability, and finish of final products at every stage of processing. This goes for every operation, from the production of raw chemical ingredients; to their blending and polymerization to produce pellets, sheets, or blanks; to the forming of finished products.

Variable frequency drives (VFDs) can provide the precise control of motor speed and torque required for a broad range of plastics processing applications, whether the motors drive pumps, conveyors, compressors, blowers, or any other equipment.

But VFDs can damage the motors they control. They induce voltage on motor shafts that causes electrical arcing through the bearings. This arcing causes pitting in the bearing, leading to fluting and catastrophic bearing failure. Bearing failure in turn causes unplanned downtime, and the colossal costs of lost production can quickly wipe out any benefits from the use of VFDs. The bearings must be protected to minimize the risk of downtime due to bearing failure.

Plastics production processes typically involve very large runs, and machine failures can shut down production, resulting in costly repairs and huge revenue losses. So when the 300 HP motor for an injection molding machine at a North Carolina plastics plant experienced premature bearing failure, plant engineers wanted to know why. Testing showed that shaft voltage discharge through the bearings was the cause of the failure.

After doing some research, plant engineers learned about AEGIS® Shaft Grounding Rings. Shaft grounding rings give electric charge on the shaft a low-resistance path to ground. So rather than arcing destructively through the bearings, voltage bleeds off harmlessly through the grounding ring. The engineers decided to try an AEGIS Ring.

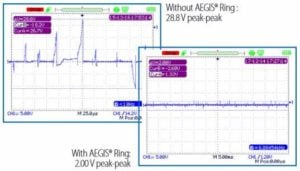

Shaft voltage readings on an injection molder's motor before and after installation of an AEGIS Ring.

Shaft voltage readings on an injection molder's motor before and after installation of an AEGIS Ring.Before they installed the ring, the motor showed shaft voltage up to 25-30 volts (peak to peak). After installation, the shaft voltage was decimated, weighing in at just a couple of volts at most. The ring was obviously working: The shaft voltage had decreased to levels too low to discharge through the bearings.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.