Most companies are constantly looking for ways to save energy. It's a quest that never ends. But it does not have to be tackled all at once. Older motors — even those that were customized for a particular system/application or those no longer in production — can be made more energy efficient through the use of variable frequency drives (VFDs). VFDs provide a simple, cost-effective means of controlling a motor's speed or torque by varying the power output to the motor. In doing so, they can not only improve process control, they save energy.

And if the output of the motor is somehow restricted through the use of dampers or other throttling mechanisms, the use of a VFD can save even more in energy costs by precisely matching capacity to varying demand and eliminating the needless waste of energy.

If a new motor would be a logical replacement for an older motor, the potential for energy savings is greater still. New NEMA Premium motors offer increased efficiencies of 5-7% for smaller motors (10 HP or less). So replacing an older standard efficiency motor with a new NEMA Premium efficiency motor controlled by a VFD could yield impressive energy savings.

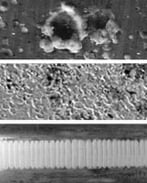

But controlling a motor with a VFD can also shorten the motor's life.  VFDs create damaging voltages on the shafts of the motors they control. Without proven, long-term shaft grounding, these voltages can discharge through motor bearings, causing electrical discharge machining in the form of pitting (tiny fusion craters in metal surfaces), frosting (widespread pitting), fluting (washboard-like ridge in the race wall), and complete bearing failure — in as little as 3 months! And the costs of bearing or motor replacement and unplanned downtime can easily wipe out any energy savings from the use of VFDs.

VFDs create damaging voltages on the shafts of the motors they control. Without proven, long-term shaft grounding, these voltages can discharge through motor bearings, causing electrical discharge machining in the form of pitting (tiny fusion craters in metal surfaces), frosting (widespread pitting), fluting (washboard-like ridge in the race wall), and complete bearing failure — in as little as 3 months! And the costs of bearing or motor replacement and unplanned downtime can easily wipe out any energy savings from the use of VFDs.

AEGIS® Shaft Grounding Rings combine direct contact and proprietary non-contact technology to provide superior grounding and protection of motor bearings for their full L-10 life. AEGIS Rings channel these damaging voltage discharges away from bearings and safely to ground, protecting VFD-driven motors and the energy savings they generate.

You can easily install AEGIS Rings yourself on any motor (even those with shaft shoulders, slingers, or other end bell protrusions), or have your local motor repair shop install them. But the simplest way to prevent VFD-induced bearing damage is to purchase a new motor with AEGIS Rings factory-installed from the manufacturer. In fact, motors factory-equipped with AEGIS Rings are offered by most major motor manufacturers.

So, if you are working on making your building, systems, or processes more energy-efficient, remember you don't have to replace all of your motors, all at once. You can replace older, less efficient motors (as they wear out) with new VFD-controlled NEMA Premium motors equipped with AEGIS Shaft Grounding Rings.

For more information on how VFDs can damage motor bearings, click here.

For more information on AEGIS Ring Universal Mounting Kits, click here.

For more information on how AEGIS Rings protect VFD-driven motors, click here.

For a list of manufacturers that offer motors with AEGIS Rings factory-installed, click here.