Permanent magnet ac (PMAC) motors are an increasingly popular substitute for induction motors. They are 2-4% more efficient than induction motors, and also have higher power density. That is, for a given hp rating, a PMAC motor is 1-2 frame sizes smaller than an induction motor. Or equivalently, PMAC motors pack more horsepower into a given frame size.

Although they are more expensive than induction motors, PMAC motors save so much energy that they usually pay for themselves within two years. And those savings keep adding up over the motor's entire lifetime, which can be 20 years or more.

Unlike induction motors, PMAC motors cannot be started on line power. They must be run by variable frequency drives (VFDs). VFDs have the same upsides and downsides for PMAC motors as induction motors. On the plus side, they offer precise control with smooth speed changes and energy savings from running at reduced speed. On the other hand, VFD output creates a voltage on PMAC motor shafts, and that voltage can discharge through the bearings. This arcing through the bearing causes bearing damage and premature failure. For both induction and PMAC motors, the solution to bearing arcing is the AEGIS® Shaft Grounding Ring.

Some have argued that shaft voltage is not a problem in PMAC motors, because of their larger airgap. But that's not true: Lab testing has proven that PMAC motors are at risk of electrical bearing damage.

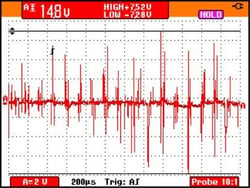

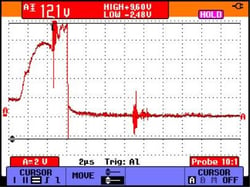

A few years ago, Electro Static Technology visited a well-known manufacturer of PMAC motors to test their shaft voltage. The results were clear: PMAC motors are subject to shaft voltage levels high enough to cause electrical bearing damage. Here are some readings from that testing. All of these readings have a voltage scale of 2 V/div. In figure 1, we see the motor's shaft voltage.

Without Shaft Grounding

The peak-to-peak voltage is 14.8V, which is high enough to cause damage. But the timescale in this image is too large to see whether discharge is occurring. In Figure 2, we zoom in to a smaller timescale. Here we see a slow buildup of shaft voltage followed by a sudden drop. This is the "smoking gun" of electrical discharge. So this reading shows an arc through the bearing. This proves that PMAC motors are at risk.

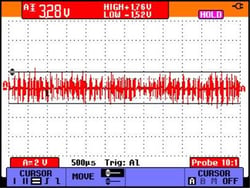

WITH AEGIS Shaft Grounding

We also tested an AEGIS Shaft Grounding Ring on the PMAC motor, as shown in Figure 3. Here, the peak-to-peak voltage is reduced to 3.28 V. This voltage is too low for bearing arcing to occur, so this is a safe level.

In summary, testing has shown that PMAC motors are at risk of electrical bearing damage, but they can be protected with an AEGIS Shaft Grounding Ring.

Marathon Motors has begun protecting their SyMAX® line of PM motors by installing AEGIS rings at the factory. AEGIS shaft grounding rings are available in all SyMAX motors, and come standard in some.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.