We got an email recently from an engineering consultant. He had recently specified a project calling for AEGIS Shaft Grounding Rings for motors controlled by variable frequency drives. Then a contractor put in a bid including, not shaft grounding, but common mode chokes or inductive absorbers. He said that they do the same thing as shaft grounding. Well, the engineer wanted to know, is that true?

They do not. To see why, let's have a look at what drives' output looks like, and then talk about what each of these devices does.

They do not. To see why, let's have a look at what drives' output looks like, and then talk about what each of these devices does.

What is Common Mode Voltage?

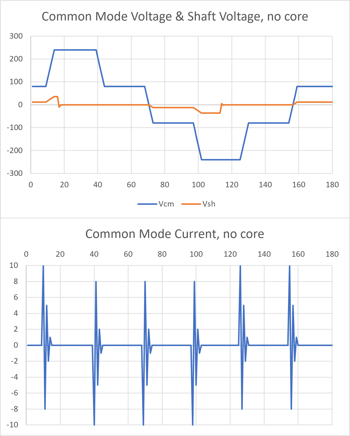

VFDs put out pulses of voltage in each of the three phases. The average of the three phase voltages is called common mode voltage (top graph, blue), and it is never zero. The average of the phase currents, the common mode current (bottom graph), is near zero most of the time, but it jumps every time the common-mode voltage changes.

The Difference Between Common Mode Voltage and Shaft Voltage

When the common mode voltage reaches the motor, it couples to the rotor by capacitance. This creates a so-called shaft voltage (top, orange). This part is important: The higher the common mode voltage, the higher the shaft voltage produced. When the shaft voltage gets too high, it will discharge by arcing through the bearings. This is shown around time = 18 on the graph: the shaft voltage drops suddenly, the smoking gun of an arc. The same thing happens around time = 115, but starting from negative shaft voltage.

This arcing causes electrical bearing damage, and it is a problem in all motors on drives. AEGIS rings prevent this damage by bleeding off shaft voltage before it gets high enough to discharge through the bearings.

How Do Inductive Absorbers Work?

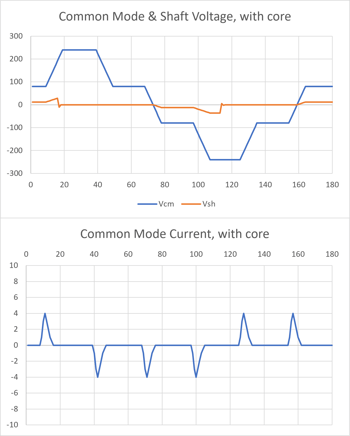

Inductive absorbers work totally differently. They decrease the peak common mode currrent, as shown in the second set of graphs. They also decrease the slope of the common mode voltage, i.e., how fast it changes. (Jargon alert: they decrease dv/dt.) But inductors do not change the maximum size/height of the common mode voltage, so they will not prevent shaft voltage buildup and discharge.

Types of Electrical Bearing Damage

In fairness, inductive cores do have their uses. In addition to shaft voltage discharge, there are two other types of electrical bearing damage: High-frequency circulating current in large motors, over 100 HP/75 kW, and rotor ground current in poorly grounded motors. Inductive absorbers decrease both of those bearing currents, and they also reduce stray/noise current from the drive.

But they do not affect shaft voltage buildup and discharge, and so cannot replace AEGIS Shaft Grounding Rings.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.