This 56-page technical handbook describes best practices for protecting motor bearings from electrical damage.

Bearing Protection Handbook

The Handbook is available from Electro Static Technology, the manufacturer of AEGIS® Shaft Grounding Rings, and explains how to diagnose electrical bearing damage caused by variable frequency drives (aka VFDs or inverters).

The Handbook is available from Electro Static Technology, the manufacturer of AEGIS® Shaft Grounding Rings, and explains how to diagnose electrical bearing damage caused by variable frequency drives (aka VFDs or inverters).

The Handbook explains in detail best practices for preventing such damage to motors of various sizes and horsepower ratings. It is ideal for plant maintenance personnel as well as motor repair shops and is available in paper form and as a pdf.

Protecting Investments

Adam Willwerth, Electro Static Technology’s sales and marketing manager:

“Users of VFD-driven motors have every right to expect uptime and reliability. A repair shop that fixes a motor’s bearing problem properly only has to do it once. Doing so is more likely to earn customer loyalty. Better yet, a shop that offers value-added services such as inspection, shaft voltage testing, vibration analysis, thermography, and that shows a customer the right preventive measures to head off future damage.

Personnel with this knowledge can now protect any motor’s bearings from electrical arcing. This protection protects a brand new motor before its installation, or a motor already in service.”

AEGIS Shaft Grounding Rings

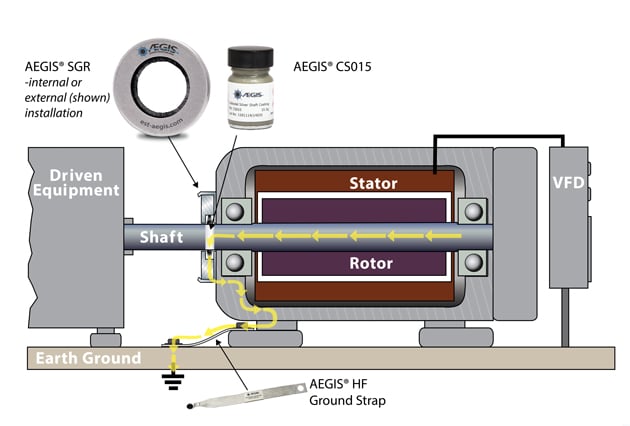

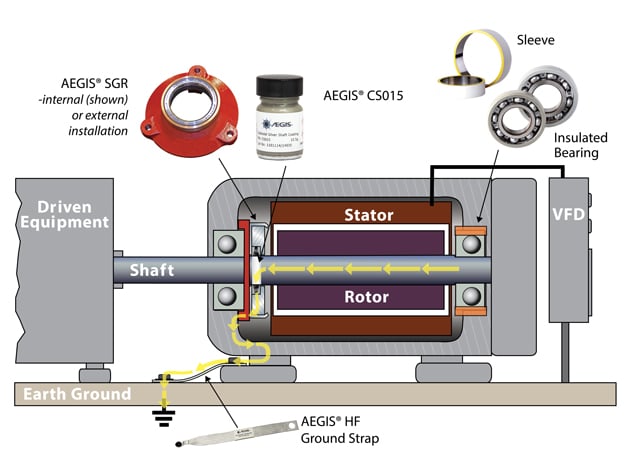

Shaft grounding rings channel VFD-induced bearing currents safely to ground. Continuous circumferential rows of conductive microfibers embedded securely in the ring’s patented FiberLock™ channel surround the motor shaft and provide millions of discharge points for harmful shaft currents. This unique design creates the path of least resistance that effectively diverts these currents away from bearings to ground.

Shaft grounding rings channel VFD-induced bearing currents safely to ground. Continuous circumferential rows of conductive microfibers embedded securely in the ring’s patented FiberLock™ channel surround the motor shaft and provide millions of discharge points for harmful shaft currents. This unique design creates the path of least resistance that effectively diverts these currents away from bearings to ground.

The microfibers themselves are specially engineered for exceptional conductivity and flexibility to minimize wear and prevent breakage. AEGIS rings are the only long-term shaft grounding technology proven effective in millions of VFD/motor applications worldwide.

Motors over 100 HP need at shaft grounding ring (usually at the drive end) and an insulated bearing at the opposite (non-drive) end.

Motors over 100 HP need at shaft grounding ring (usually at the drive end) and an insulated bearing at the opposite (non-drive) end.For more information:

- Contact: sales@est-aegis.com

- Call Toll-Free: 866.738.1857

- TEL: 207.998.5140

- FAX: 207.998.5143