Motors run by variable frequency drives can fail due to electrical bearing damage. Several products have been developed over the past 20 years to deal with this problem. In this article, we're going to look at just two: Carbon shaft grounding brushes and AEGIS® Shaft Grounding Rings.

Carbon brushes have been around for over 100 years, and are mostly used in dc motors' commutators. They are an old technology that was repurposed to address a new problem.

AEGIS Rings, on the other hand, were developed specifically to prevent electrical bearing damage.

One obvious difference is size and shape. Carbon brush holders are close to an inch (2.54 cm) thick, while AEGIS rings are only about 3/10" (7.5 mm) thick. This makes AEGIS rings a much better fit for close-coupled installations.

Carbon brushes are relatively high-maintenance. They use springs in a holder to press the brush against the motor shaft. No matter how ingeniously designed the holder is, the assembly must be inspected and adjusted occasionally to maintain good shaft contact. AEGIS Rings, on the other hand, are all of one piece. The ring holds an array of conductive microfibers around and lightly touching the shaft. No adjustment is needed.

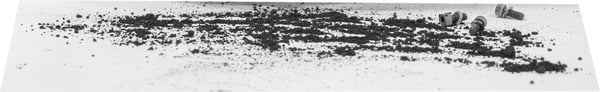

AEGIS Rings also show very little wear. Lab testing estimates a usable lifetime of 200,000 hours. Carbon brushes, on the other hand, do wear. Sometimes, quite a lot. This wear has other drawbacks beyond the need for occasional maintenance and/or replacement.

Firstly, between wear and maintenance requirements, carbon brushes should not be installed inside motors. We have seen bearings fail due to grease contamination by carbon powder worn off of grounding brushes. The dust can potentially damage the windings, as well. AEGIS Rings CAN be installed inside motors. Several motor manufacturers offer lines with AEGIS factory-installed internally.

Because they can't be installed inside motors, carbon brushes also can't be used in washdown duty or explosion-proof motors. In contrast, LEESON/Regal Beloit offers washdown duty motors with AEGIS inside, and UL has approved a set of procedures for installing AEGIS Rings inside XP motors. XP motors are also available with AEGIS factory-installed. Marathon Motors (Regal Beloit) installs AEGIS rings in Hazardous Duty™ motors with part numbers ending "-P." AEGIS rings are available as a mod in WEG and Baldor (ABB) explosion-proof motors.

In fairness, AEGIS Rings are not perfect. Carbon brush manufacturers note that new brushes decrease shaft voltage more than AEGIS Rings. This is true, but only when the carbon brushes are new:

Over the space of a few months, a film called the patina builds up on the shaft. The patina is necessary for the brush to slide smoothly along the shaft and is beneficial for dc charge transfer. But tests have shown that the patina increases the impedance (resistance) for high frequency ac. So as the patina builds up, the brush can less effectively discharge high frequency shaft voltage.

On the other hand, AEGIS Rings hold the shaft voltage steady at less than 5V peak. Moreover, shaft voltage under 5V does not cause appreciable damage. And you don't need to take our word for it. Among other sources, that 5V limit comes from GKE, inventor of the Bearing Predictor "Beppe" and one of the world's experts on electrical bearing damage.

So, while no form of shaft grounding is perfect, AEGIS Rings offer several unique advantages that make them the best option on the balance.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.