Underwriters Laboratories (UL) has an approved set of procedures for installing AEGIS shaft grounding rings inside explosion proof (XP) motors. XP motors with AEGIS rings installed according to these procedures may be used in hazardous environments, Class I: Division 1.

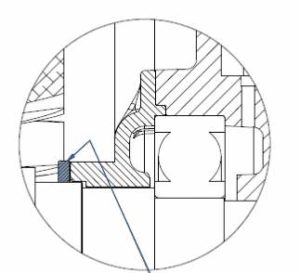

The following diagrams are the approved installation locations inside the XP motor.

Detail of AEGIS Shaft Grounding Ring in XP motors

Detail of AEGIS Shaft Grounding Ring in XP motors

Note: In Class I: Division 2 designs. Because shaft grounding devices must be installed inside explosion proof enclosures (as per IEEE 303) for Class I: Division 2, they may not be installed internally or externally in/on a non-XP motor.

At this time, Marathon Electric is the only electric motor manufacturer marketing XP motors with AEGIS shaft grounding protection installed inside. They range from 3 HP (182T Frame) to 50 HP (326T Frame) and Marathon Electric will install AEGIS Rings in larger models. For more information on Marathon Hazardous Duty motors with AEGIS Inside. For catalog numbers and pricing, see the highlighted “-P” motors on the Hazardous Duty™ pages of the 2014 catalog.

UL Approved Electric Motor Repair Companies

To install AEGIS rings in explosion proof motors in a hazardous environment, a motor repair shop must first be UL approved to work on all XP motors. They must then apply for certification for the addition of adding shaft grounding to their UL binder and then demonstrate adherence to the additional set of procedures required for installing shaft grounding inside of XP motors.

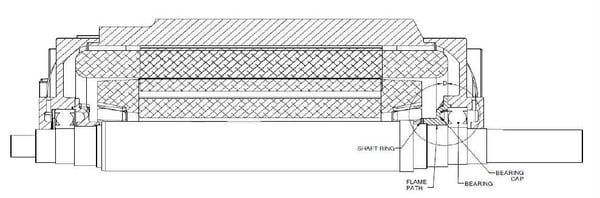

Motor repair shops with UL certification to work on XP motors and certification of their ability to add shaft grounding can "rework" any size explosion proof motor and then re-nameplate the motor as explosion proof. The drawing below was created by UL to show where the ring must be installed to comply.

Diagram of location to install AEGIS Rings inside the XP motors

Diagram of location to install AEGIS Rings inside the XP motors