Variable frequency drives (VFDs), or inverter drives, allow precision RPM and torque control of electric motors. In some applications, they can save up to 30% on energy costs. However, VFDs are not without problems, and can induce unwanted shaft voltage. Without effective protection, shaft voltage can cause premature bearing failure and thus motor failure.

The National Electrical Manufacturers Association (NEMA) and other institutions recommend that new motors be equipped with effective bearing protection. But whereas insulation is designed according to the latest standards to protect the windings, bearings are often neglected. In order to be truly suitable for VFD operation, a motor should additionally have long-term bearing protection. Often, this is not given sufficient consideration, and this omission leads to expensive downtime.

Risk of motor damage during VFD operation

Damage to windings and bearings can result from the repetitive and extremely fast impulses produced by modern VFDs in the motor. VFD output voltage’s fast rise time puts stress on the motor windings. Under some circumstances, “reflected waves” can produce voltage spikes up to twice as high as the drive’s specified output voltage.

New bearing (left) and one with advanced electrical damage (right)

New bearing (left) and one with advanced electrical damage (right)In addition to winding damage from fast voltage rise times, the imbalance of drive output voltage produces a voltage difference between the motor shaft and frame (“shaft voltage”). This leads to a voltage across the bearings, and this bearing voltage can cause arcing when it discharges. This arcing erodes the bearing surfaces and leads to premature failure. Each arc creates a microscopic pit, and in aggregate, these pits give the bearing a matte, frosted appearance. Over time, fluting occurs: A washboard-like series of ridges forms, resulting in increased bearing noise and vibrations. By the time fluting has developed, the motor will make a piercing screech when it runs, and the bearing must be replaced before it fails catastrophically.

A new bearing and one with advanced electrical damage are shown in the figure above (click to enlarge).

Electrical bearing protection

AEGIS Shaft Grounding Rings

AEGIS Shaft Grounding RingsIn most cases, a reliable and cost-effective way to minimize electrical bearing damage and increase the reliability of VFD-controlled motors is to use an AEGIS® Shaft Grounding Ring. (In addition to an AEGIS ring, motors larger than 100 hp/75 kW also require an insulated bearing at the opposite end from the grounding ring.)

AEGIS rings encircle the shaft with thousands of highly conductive microfibers, which are secured in a patented FiberLock channel. The microfibers create a very low-resistance path from motor shaft to frame. Rather than arcing through the bearings, current from the shaft will instead travel through the grounding ring. The microfibers ride lightly on the shaft with very low friction, so they are much less subject to wear than other forms of shaft grounding. Moreover, AEGIS rings can be scaled up to arbitrarily large shaft diameters.

Simple proof of efficacy

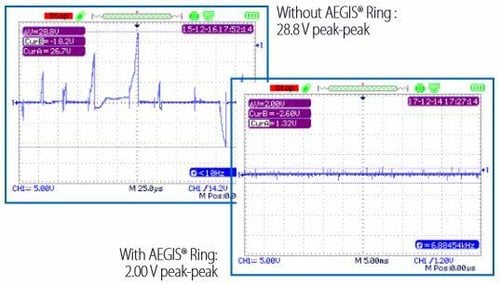

The effectiveness of shaft grounding rings can be detected by simply measuring the shaft voltage with an oscilloscope. Without shaft grounding, the voltage profile appears in high voltage peaks and steep discharge edges. After applying the shaft grounding ring, a virtually flat line appears.

AEGIS Shaft Grounding Rings have proven their value in millions of installations worldwide, mainly in North America and Asia. Many motor manufacturers, such as ABB Baldor, WEG, and Regal Rexnord, use factory-installed shaft grounding rings as standard or as options for certain motor series, so that the operation of the VFD does not have any harmful side effects on the motors.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

![]() To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.