1. Motors run on variable frequency drives (VFDs) need protection against bearing current

VFDs are widely used for energy savings. But without bearing protection, those savings can be lost. Because VFD output power is not balanced (i.e., the three phase voltages don't cancel out), VFDs create a capacitive voltage on the shafts of the motors they control. This shaft voltage will try to discharge to ground by the lowest-resistance path available. Usually, the path of least resistance lies through the bearings, so that's where discharge will occur, in the form of an electrical arc. These arcs create pits in the bearing surface. Although these pits are individually tiny, arcing can occur thousands of times per second, and each arc creates a new pit. The damage due to pitting is cumulative and can cause bearing failure in as little as a few months.

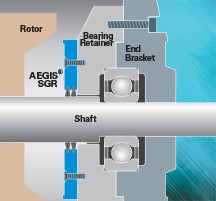

AEGIS® Shaft Grounding Rings offer a lower-resistance path for this discharge current. Because the bearings have higher resistance than an AEGIS ring, these currents preferentially flow through the ring, not the bearing. Without discharge current constantly flowing through the bearing, the bearing will last as long as it was designed to, and users will be spared the costs of frequent motor repair and the downtime it entails. For an ROI analysis of AEGIS shaft grounding, see this post.

2. Internal installation protects the AEGIS Ring

Compared to other methods of shaft grounding, AEGIS rings are highly resistant to contamination and other environmental factors. Nevertheless, excessive amounts of dust, debris, and grease can interfere with the ring's function, and mounting the ring inside the motor frame protects it from these detrimental influences.

This is especially important in severe environments. In cooling towers, washdown environments, and some potentially explosive atmospheres, internal installation is necessary.

3. Factory installation saves you time

While AEGIS rings are not difficult to install, it's even easier, and quicker, to buy a motor with a ring already installed.

4. Factory installation saves you money

A motor with AEGIS factory installed will cost less than a similar motor without AEGIS plus the cost of the ring, plus the value of the time it takes to install the ring.

5. You've got options

Many of the best-known motor manufacturers offer motor lines with AEGIS factory-installed inside. Baldor-Reliance (ABB), U.S. Motors (Nidec), WEG Electric, LEESON and Marathon (Regal Rexnord), and GE (Wolong) all offer AEGIS inside their inverter duty motors. You can find a full list of motors with AEGIS rings factory-installed here.

If all of that was not enough, AEGIS Shaft Grounding Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of shaft grounding offers a warranty like this.

learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.