Part 6 in a series of questions and answers from our Q&A webinars.

Q1: Do you need a shaft grounding ring and a high frequency bonding strap, or is just the strap enough?

A1: You definitely need a grounding ring. You may or may not need a grounding strap, too. Motor and drive manufacturers recommend them. Here's what's going on:

Three phase power off the line is balanced. The voltage in each of the three phases always cancels out; the sum of the three voltages is zero. Power from a VFD is unbalanced. The voltages in each phase do not cancel each other out. So when the power gets to the motor's stator windings, there is a net voltage. This net, or common mode, voltage also changes rapidly. When the drive switches a phase on or off, the net voltage changes by hundreds of volts in under a microsecond. Whenever voltage in a line changes rapidly like this, you get high frequency current leaking out through stray capacitances. This stray current has to get back to the drive somehow. We talk about "ground" and grounding, but for our purposes, ground is just a part of the path back to the drive.

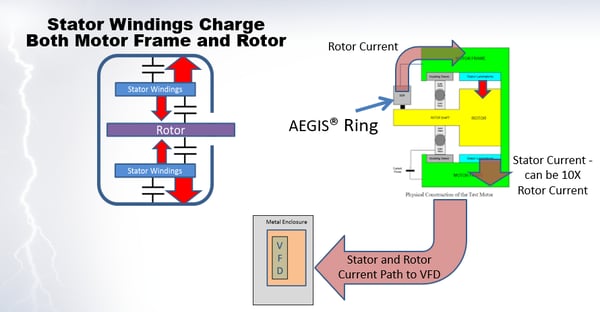

That's what this image shows. Rapidly changing voltage in the stator windings makes current leak out onto the rotor and the motor frame. Without shaft grounding, current from the rotor will arc through the bearings to get to the frame and then ground. In the image above, it's called rotor current, but it's more often called shaft current or shaft voltage discharge. If you put an AEGIS ring on the shaft, then this current can get to the frame without arcing through the bearing. That's what shaft grounding rings are for.

Meanwhile, you have a large amount of current leaking from the windings onto the frame. In the image, it's called stator current. This needs to run to ground, too. If the frame's ground connection is good, no problem. But if the motor is poorly grounded, this current often ends up jumping from the frame through the bearings to the shaft, then through the coupled equipment's bearings, then to ground. This destructive current is called rotor ground current. It can kill both the motor's bearings and the equipment's bearings.

To clarify the terminology in the image: rotor current comes from the rotor; stator current comes from the stator. If the grounding is good, stator current just flows to ground. If the grounding is poor, stator current will instead arc through the bearings as rotor ground current.

What a grounding strap does is ensure that current from the frame can go to ground. The strap gives a nice low-resistance path from the motor to the equipment, so stator current flows through it instead of through the bearings.

Now, getting to your question: If you only have a grounding strap, and no grounding ring, you will prevent rotor ground current from damaging the bearings. But you will still get damage from shaft voltage discharge, unless you also have a grounding ring.

Q2: What's the difference between an AEGIS HFGS and a regular braided grounding strap?

A2: Any braided grounding strap will do the job. The wider it is, the more surface area it has, and the better it works. The surface area is important because these are high frequency currents, and they travel on the surface of conductors. It's called the skin effect. The more surface area a conductor has, the less impedance (resistance) it has to high frequencies.

AEGIS HFGS are easier to use because you can get them with bolt holes punched into them. You can size them based on NEMA/IEC frame size, and just attach them through the bolt hole in the motor foot. But otherwise, they're equivalent.

Q3: The grounding strap gets attached to the motor at one end. What is the other end of the strap attached to?

A3: Good question. You want to be sure that from motor frame to earth ground you have good conductors with as few connections as possible. Like the I-beam frame of a building: steel is a good conductor. Concrete is not. So ground wires should not terminate at concrete. We've been to plants where they have a grounding mat, which is like a grid of cross-hatched rebar, buried in the ground.

It also helps to use the strap to bond the motor frame to the driven equipment's frame. If both the motor and equipment are poorly grounded, this won't help current get back to the drive, but it will prevent rotor ground current from scorching the bearings.

Q4: What kind of amperage on a grounding strap is too high? We have a spec of less than 5 amps, and that seems high, even for a 300 hp motor. Could this be phase imbalance, since our machines only use a VFD to start?

A4: The current capacity of a grounding strap depends on its width and thickness. We size ground straps based on motor specs, so the larger the motor, the higher current capacity the strap will have. On a drive, stator ground current comes in pulses. Those pulses range from 20 amps for small motors up to 200 amps for very large ones.

But if you're on line power and seeing 5 amps, there's something else going on. You shouldn't be able to power another piece of equipment with the ground wire. You're right that the ground current you see is a symptom of an underlying problem. Whether it's phase imbalance or something else, we can't say.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.