Part 4 in a series of questions and answers from our Q&A webinars.

Q1: Is the grounding of the motor important, and if so, what kind is needed?

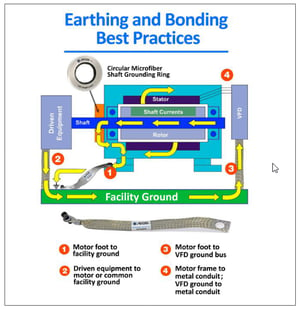

A1: AEGIS rings bleed charge off the shaft, but that charge then needs to get back to the VFD somehow. It's important that there be a good, low-impedance path from the motor frame to the drive. To be clear, that is what we mean by "grounding": a low-impedance path from frame to drive. Even if "grounding" is not strictly the right term when that path doesn't go through the facility ground. The return path often does lead through the ground, but if you use a high-quality VFD cable, that will carry most of the return current.

Regardless of the return path: You can have what are called rotor ground currents when the motor is not well-grounded. Rotor ground current jumps from the frame through the bearings, and then goes to ground through the load. These currents are doubly destructive, because they arc through motor and equipment bearings.

Either way, these are high-frequency discharges, and with high frequency electricity, you have the skin effect where current only travels close to the surface of a conductor. So we recommend a high frequency grounding strap, with high surface area. You bond one end of the strap to the motor frame, and the other end to the driven equipment or other well-grounded conductor. There are also excellent VFD cables with special features to decrease the impedance, but some of them get pretty expensive.

Q2: Sometimes we see shaft voltage even on motors that are not controlled by VFD. Do you recommend AEGIS rings in that case?

A2: Yes, they're often used on motors without drives, and on generators for that matter. Besides VFDs, this can come from static, power surges, and other sources. When in doubt, use a scope and measure the shaft voltage. If there's voltage across the bearing, regardless of the source, it can discharge through and damage the bearings.

Q3: Do shaft grounding rings work if they get grease on them?

A3: There's a certain amount of grease in every application, whether small or large. Our microfibers are good at wiping away grease and oil as the shaft spins. If you're concerned about large amounts of grease, there are other options. First, we recommend mounting the ring inside the motor whenever possible. If you can't mount inside, we recommend a slinger or an O-ring to cut down the amount of grease getting to the fibers.

Q4: If the ring is mounted internally, is it still necessary to use colloidal silver shaft coating?

A4: We have several motor manufacturers who install SGRs inside their motors. Not one of them uses colloidal silver. A big part of the silver coating's purpose is to prevent rust or other oxidation on the shaft. If you choose a good, stable position on the shaft to mount the ring inside, oxidation is less of a problem.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.