Q1. How you install grounding in concrete? I have a pump being retrofit with a new VFD.

A1. For safety grounding, if the pump is on the ground floor, you'll want to mount a copper rod in the concrete. How deep you need to drive it will vary with the local electrical code; it could be six or eight feet. If it's on a higher level, you'll need to ground the motor frame through the building's structural steel. Exactly how you do that will vary.

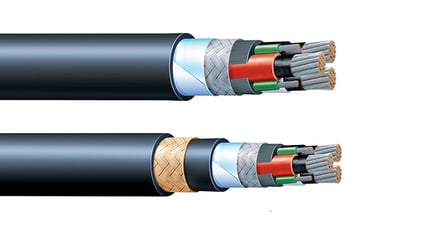

But that's safety grounding. For bearing protection, you'll also want to use proper VFD cable as recommended by the drive manufacturer. You usually want either three ground wires, symmetrically arranged, going back to the drive, or at least one ground wire and mesh or shielding. Both of these types of cable give a good, low-impedance path back to the drive for high frequency current. Without the right cable, you can get what's called rotor ground current, which damages motor and load equipment bearings. (See more here.)

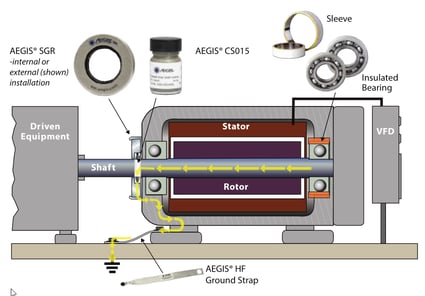

An AEGIS ring can protect the motor bearings from rotor ground current, but it can't protect the equipment's bearings from it. You still need proper cable with an AEGIS ring. For a belt-and-suspenders approach to rotor ground current, you can also bond the motor frame to the driven equipment with a high frequency grounding strap like the AEGIS HFGS.

Q2. My motor has one insulated bearing to block high-frequency circulating current. Why doesn't that also stop EDM/shaft voltage discharge current; why do I still need shaft grounding?

A2. In order for circulating current (of any frequency) to flow continuously between the motor frame and rotor, arcing must occur through both bearings. If one bearing is protected by insulating it, or using a nonconductive rolling element, then the other bearing will be protected as well.

This is because circulating current flows through each bearing in opposite directions: shaft to frame at one end, and frame to shaft at the other. If current can flow onto the shaft at one end, but not off at the other, then charge will quickly build up on the shaft and stop further flow. To use a water/current analogy, water can flow freely through a tube (neither bearing insulated). But if you seal one end (insulate a bearing), then you stop flow: once the tube is full, you can't fit any more water in.

So insulating one bearing protects both bearings from circulating current. This works both for VFD-derived high frequency circulating current in motors over 100 hp (75 kW), and low frequency circulating current in motors on line power over 300-500 hp (225-375 kW).

Shaft voltage discharge current is different: It flows in the same direction at each end. So if you insulate one bearing, current can still arc unencumbered through the other bearing. But if you also put a shaft grounding ring at the uninsulated end, the current that would arc through the bearing instead passes harmlessly through the grounding ring.

Summing up: One insulated bearing can't protect the other bearing from shaft voltage discharge, and an AEGIS ring can't protect the opposite-end bearing from circulating current. But in combination, at opposite ends, they protect both bearings against both types of bearing current.

AEGIS Shaft Grounding Rings come with a 2-year extended warranty against bearing fluting damage. No other form shaft grounding offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and – pandemic restrictions permitting – we can also visit your facility to review your exact application.