Part 17 in a series of questions and answers from our Q&A webinars.

Q1. What is the magnitude of the current coming off the shaft? Is it hazardous?

A1. No need to worry. If you put your finger on the running shaft of a motor on a drive, with or without an AEGIS ring, you wouldn't feel anything. It's not like licking a 9V battery.

Whether it's moving through a bearing or a grounding ring, current from the shaft comes in pulses. Most of the time, nothing is happening, and then there's a sudden tiny spike of current, and then back to zero. Without shaft grounding, you might have spikes of 500 milliamps that last for tens of nanoseconds. With shaft grounding, the current spikes will be much smaller, but more frequent. Either way, most of the time nothing is happening, and when the current does flow, it's very brief. So the average (rms) current from the shaft is very small.

When shaft voltage discharges through a bearing, it creates a tiny arc. Although the total energy in this arc is small, the area where it's released is also small. The energy density is high enough to damage the bearing. If you put your finger on the shaft (mind the keyway!), then capacitive current could flow across your skin to the ground. But this current's energy would be spread all across your skin, so the energy density would be too low for you to even notice.

Q2. As the shaft turns, the fibers overlap it in the direction of rotation. If the motor were bidirectional, what effect would that have?

A2. There are many systems with a motor working both clockwise and counterclockwise. Cranes and winches are a couple of examples. And this is no problem. Our testing indicates there's no limit to the number of reversals AEGIS microfibers can tolerate.

There are a couple of reasons they stand up so well to reversal. AEGIS fibers are pretty densely packed into the ring. Think about trees in a forest. An isolated tree might get blown over by whipsawing wind, but a whole forest can survive stronger winds. The AEGIS Ring also has a Fiberlock Channel in it that locks the fibers into place.

Between the fiber density and the fiber lock, Shaft Grounding Rings tolerate reversals without any problem.

Q3. How do you safely place a scope lead on a rotating motor shaft?

A3. With caution. That's the main thing. You want to keep your hands away from any fast-moving objects - motor shafts, belts, fans...

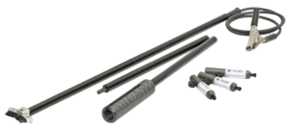

Some of the accessories from the SVP-KIT-9100MB: shaft grounding simulator with alligator clamp lead, oscilloscope probe holder and wand, and shaft voltage probe tips.

Some of the accessories from the SVP-KIT-9100MB: shaft grounding simulator with alligator clamp lead, oscilloscope probe holder and wand, and shaft voltage probe tips.Most of our oscilloscope bundles include an accessory kit, SVP-KIT-9100MB. We also sell the accessory kit separately. The kit includes a wand that you can use to touch a probe tip or shaft grounding simulator to the motor shaft. You don't technically need the wand to safely extend your reach. We have had customers jury-rig their solutions, ranging from custom-machined rods to duct tape on broomsticks. We don't exactly endorse broomsticks as shaft voltage testing accessories, but if it works...

It's actually pretty easy to touch the probe tip to the shaft. It's a little trickier to connect the probe ground clamp - it's a little alligator clip on about a four-inch (10 cm) cable. What usually works is to connect a larger alligator clamp to a lug or piece of bare metal on the motor frame. Then you connect the ground clamp to the larger clamp's wire. The accessory kit I mentioned includes a larger alligator clamp for this.

AEGIS Shaft Grounding Rings come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

![]() To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.