Part 13 in a series of qustions and answers from our Q&A webinars.

Q1: Can we avoid electrical bearing damage by using conductive grease?

A1: We don't recommend it, for a couple of reasons. For one, this grease is made conductive by adding conductive particles to it. You don't want any particulate matter in the bearing: Even very small particles can scratch the races and rollers. For another, these greases have lower electrical resistance than ordinary grease, it's true. But you still get arcing when shaft voltage discharge occurs. So electrical damage will still be done. Between these two sources of damage, conductive grease is not a viable solution. What we've seen is that failure still occurs, whether from abrasion or electrical damage.

Q2: We had a customer with an SGR on a motor, & he reported that the conductive fibers curled back and no longer maintained contact with the shaft. This motor had an insulated bearing that still ended up with fluting. We're thinking there was too much current for the SGR to handle. Is there a heavier-duty grounding ring available?

A2: Yes, we do have heavy duty AEGIS® rings, the PRO Series. If your motor is over 600 volts ac, or over 500 hp ac and low voltage, or you have a dc motor over 300 hp, you want a PRO ring. Our standard SGR has two rows of conductive microfiber. The PRO ring has six rows. If you have an SGR on your motor and you see fibers missing or melting or burnt - we don't see it often, but it can happen - then you should consider a PRO ring. Nuclear & other power generation, larger motors in processing industries, have all had good success record over 10 years.

Those numbers aren't hard, fast rules. We recommend PRO rings for ac motors at 500 hp and above. But some applications need a PRO at 300 or 400 hp.

Q3: Have you developed AEGIS rings for generators?

A3: Yes, we recommend our PRO rings for generators as well as for large motors. Generators often take our extra-robust rings, the PROMAX series. But PRO rings get used in all kinds of generators: Wind turbines, cogeneration, gas...

Q4: Some VFD panels include inductors/chokes to reduce capacitance's effects in the motor. How much more effective is the AEGIS grounding system than inductors?

A4: Those inductive filters don't address the same problems as AEGIS rings. AEGIS rings dissipate motors' shaft voltage, which is produced by the common mode voltage of the drive's output. This shaft voltage is a problem in all unprotected motors on drives, no matter what size. AEGIS rings pretty much eliminate the risk of that shaft voltage arcing through the bearings.

Now, chokes or "inductive absorbers" add impedance to the power cables, and they actually reduce common mode current, which is a different thing. It causes problems of its own, and these filters reduce those problems. Just for a few examples, common mode current causes high frequency circulating current in large motors, over 100 hp (75 kW). And they reduce rotor ground current in poorly grounded motors. But they don't do all that much for small, well-grounded motors.

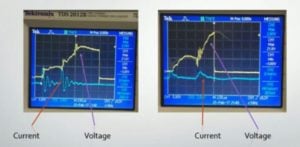

Shaft voltage (yellow) without and with an inductive filter (left and right, respectively). The shaft voltage builds up and arcs through the bearing regardless of the inductor.

Shaft voltage (yellow) without and with an inductive filter (left and right, respectively). The shaft voltage builds up and arcs through the bearing regardless of the inductor.Most importantly, these filters don't reduce common-mode voltage. So they don't reduce shaft voltage, so they don't remove the need for an AEGIS ring. Every motor on a drive, whether it's small or large, whether it has an inductive filter or not, is going to have shaft voltage and need an AEGIS ring.

Q5: Do AEGIS rings eliminate static electricity in textiles & paper on rollers?

A5: Yes. What kind of ring you'd need would depend on just how severe the static is. But our company actually got its start making antistatic brushes. They use the same, or similar, conductive microfibers as our AEGIS rings.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.