Enhancing System Reliability through Vibration Technology, by James Sylvester, is a  new manual of predictive maintenance techniques. This handbook is written with hands-on mechanical tradesmen in mind. But managers, especially maintenance managers, will also find it useful, particularly the first few chapters.

new manual of predictive maintenance techniques. This handbook is written with hands-on mechanical tradesmen in mind. But managers, especially maintenance managers, will also find it useful, particularly the first few chapters.

The book focuses throughout on real-world applications and case studies, rather than theory. As the title implies, the book focuses on vibration analysis. But it also touches upon other nondestructive tests, like thermography, ultrasonic inspection, and shaft voltage testing.

The text is broadly divided into five Parts: Introduction to Condition-based Maintenance; Condition Monitoring Management Processes; Vibration Analysis Condition Monitoring Techniques; Performing Vibration Analysis; and Balancing. There is also an Appendix comprising 17 case studies. The full table of contents is listed on the order page.

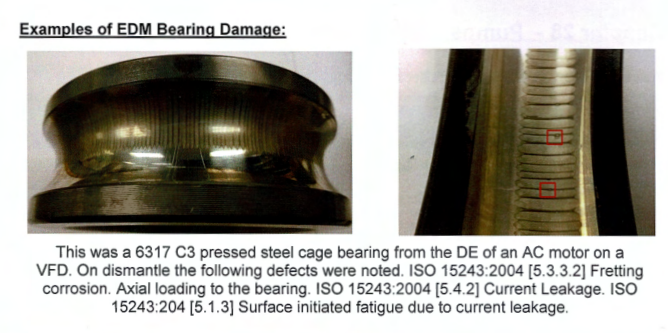

In addition to those in the appendix, there are dozens of mini-case studies and applications throughout the other chapters. Further, in keeping with the real-world focus of the book, almost every illustration is taken from a real-life situation. For example, here is electrical bearing damage to a VFD-controlled motor without proper bearing protection:

For more detail, see the text's brochure. Or to order your copy, see the Training Materials page at theseasonedanalyst.guru.

For more information on electrical bearing damage, see the AEGIS® Shaft Grounding Rings or the other articles on this blog.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.