Whether a failing electric motor is already in the repair facility or is still at the plant and needs repair, there is crucial information which MUST be considered to make sure it will stay up and operating after it is repaired.

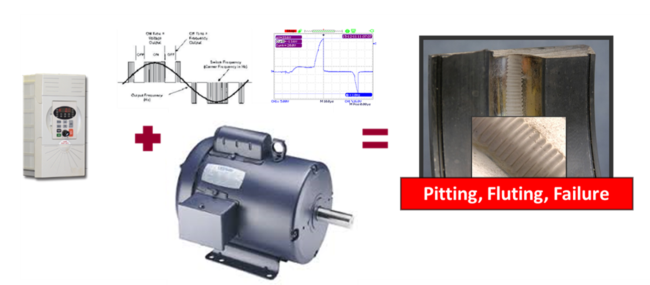

1. Was the Motor on a Variable Frequency Drive?

Today, variable frequency drives (VFDs) are commonly used to control the speed of motors. They not only provide precise process control for improved productivity and product quality, they also save energy. But, VFDs can also damage motors. They induce currents on motor shafts that discharge through the bearings, causing pitting, fluting, and in many cases catastrophic motor failure. Without bearing protection, any savings from the use of VFDs can be quickly wiped out by system downtime and the cost of replacing motors.

2. How Long Has the Motor Been in Service? Does the Motor Have a History?

New VFD-driven motors should have bearing protection installed at startup. If the motor’s been in service, adding a bearing protection ring will not fix damage which has already occurred. Bearing failure accounts for about half of all motor failures, and when the motor is on a VFD, electrical bearing failure is the most likely root cause. If bearings are replaced repeatedly a bearing analysis will point to the cause or causes of failure. They may be electrical, mechanical, or lubrication failure, or even a combination of all three. If the motor is in failure mode and on a VFD, a shaft grounding ring can be installed when the motor is repaired.

3. Has the Motor Been Repaired? If so, were the Bearings Inspected and Did You Receive a Bearing Failure Analysis?

At the time of a VFD-driven motor repair, cutting and inspecting the motor bearings will often provide vital information needed to make the best repair recommendations. Detection of electrical discharge machining pits or fluting in the bearings often requires repair services.

- Bearings should be checked for electrical discharge machining effect (EDM); pitting, frosting, fluting

- Installing a Shaft Grounding Ring (AEGIS® SGR or PRO Series) on any motor operated on variable frequency drives (VFD)

- Insulating a motor bearing with an insulated sleeve; coating bearing housing with insulating material; adding a hybrid ceramic ball bearing or ceramic coated bearing to the repair for motors over 100 HP (75kW).

4. Do You Have Shaft Voltages?

Measuring the shaft voltage on VFD driven motors provides valuable information to determine if there is a potential risk of bearing damage from electrical bearing discharges. Surveying and documenting shaft voltage readings and waveforms will assist in determining the appropriate mitigation or solution. Note: The best time for shaft voltage measurements is during initial start-up in new or repaired motors. Shaft voltage measurements should be incorporated into preventive and predictive maintenance programs and may be combined with vibration analysis, thermography or other services.

5. AEGIS Handbook

Referring to the Bearing Protection Handbook provides best practices guidance for motor operated by VFDs. Downloading and reviewing this handbook puts valuable information at your fingertips and when followed will help improve the reliability and operation of any size motor.

ANSI/EASA Standard AR100-2010, Section 2, Mechanical Repair: 2.2 Bearings “Bearings should be inspected for fretting, fluting, frosting, scoring or other damage.” Best practices for Bearing Protection, Shaft Voltage Testing, and Bearing Inspection.