This article is guest written by eMotors Direct, your trusted AEGIS Shaft Grounding Ring installer in Canada.

AEGIS® Shaft Grounding Rings are essential for protecting motor bearings from electrical damage caused by variable frequency drives (VFDs). However, improper installation can undermine their effectiveness, leaving motors vulnerable to costly damage. In this article, we’ll explore five common mistakes when installing AEGIS Shaft Grounding Rings and provide solutions to ensure a smooth and effective installation.

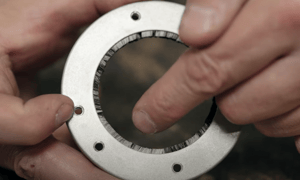

1. Not Ensuring the Fibers Are in Contact with the Shaft

Why This Is a Problem:

The microfibers inside the AEGIS ring must be in constant contact with the motor shaft to create an effective electrical pathway. If the fibers fail to make full contact, the grounding ring cannot adequately divert electrical currents, putting the motor bearings at risk.

How to Avoid It:

When removing the AEGIS ring from the box, ensure you do not crush the fibers. Inspect the fibers during installation to ensure they are aligned correctly and fully in contact with the shaft. Manually rotate the shaft after installation to check for any inconsistencies in contact.

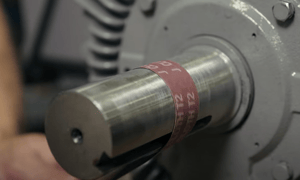

2. Not Cleaning the Shaft

Why This Is a Problem:

A dirty shaft can impede the grounding ring’s ability to function. Contaminants like dust, paint, grease, or rust increase resistance, preventing the ring from effectively diverting electrical currents, which can lead to bearing damage.

How to Avoid It:

Clean the shaft thoroughly with an industrial-grade solvent or degreaser to remove any dirt, grease, or rust. If there is paint on the shaft, use soft sandpaper to remove the paint from the shaft. Ensure the shaft is dry and free of residue and debris before installing the grounding ring.

3. Reusing Worn-Out Grounding Rings

Why This Is a Problem:

While AEGIS Rings are designed to last up to 200,000 hours (over 20 years) in ideal lab conditions, real-world factors can shorten their lifespan. The conductive microfibers can wear down over time or become damaged during installation, removal, or motor repairs. Reusing a worn or damaged ring reduces its effectiveness, leaving motor bearings unprotected from harmful electrical currents.

How to Avoid It:

Do not reuse previously installed AEGIS Grounding Rings. Replace the ring when the fibers appear damaged or the ring shows signs of degradation, ensuring ongoing protection for the motor bearings.

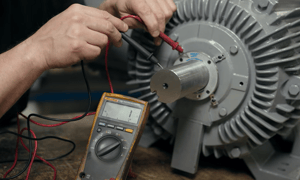

4. Not Testing the Installation

Why This Is a Problem:

Skipping post-installation testing can lead to undetected issues, such as poor contact or ineffective grounding. Without testing, you may not know if the ring is working correctly, and the motor may be at risk of electrical damage.

How to Avoid It:

After installation, use a continuity tester or multimeter to verify that the grounding ring is working as expected. Regular testing helps ensure that the ring is properly diverting electrical currents and providing effective protection for the motor.

5. Using Non-Conductive Materials

Why This Is a Problem:

When installing AEGIS Shaft Grounding Rings, using non-conductive thread-lock or adhesives can disrupt the electrical pathway between the grounding ring and the motor frame. Non-conductive compounds act as insulators, reducing the effectiveness of the grounding system and leaving motor bearings vulnerable to electrical damage.

How to Avoid It:

It’s recommended not to use thread-lock when installing AEGIS Rings. Similarly, avoid standard adhesives that act as insulating barriers. Instead, use conductive adhesives or mounting brackets recommended by AEGIS to ensure both secure installation and proper electrical grounding. Always follow the installation guidelines provided in the AEGIS manual to guarantee optimal performance.

Conclusion

Proper installation of AEGIS Shaft Grounding Rings is essential for safeguarding motor bearings from electrical damage. By avoiding common installation mistakes, such as failing to use colloidal silver, not ensuring fiber contact, or not cleaning the motor shaft, you can ensure your grounding system performs optimally.